FM Approvals issues unprecedented certification for automated fire pump testing system

In November, FM Approvals issued the first certification for an automated fire pump testing system to MECON GmbH after their Fully Automatic Churn Testing System (FACTS) successfully completed the testing requirements of FM Approvals Standard 1330 for Fire Pump Monitoring and Automated Testing.

Performance testing for FM 1330 confirmed FACTS’ fulfillment of general requirements related to temperature and voltage range, dielectric strength, extraneous transients, surge transients, electromagnetic compatibility, enclosure suitability, and sensors and actuators. FACTS’ sensors met minimum/maximum monitoring point verification, response time, supplemental power source, cybersecurity, among other requirements. Additional aspects of FM Approvals Standard 1330 include:

- Mitigating risks to individuals in the pump room

- Ensuring proper function of the fire suppression system during fire incidents while testing

- Preventing damage to the fire pump package and the fire suppression system

This has led to the redundancy of key safety functions and enhanced reliability of the fire suppression system. Automation enhances reliability through regular testing and deviation reporting. When paired with enhanced security valve supervision, this system can significantly reduce the frequency of physical testing and inspections.

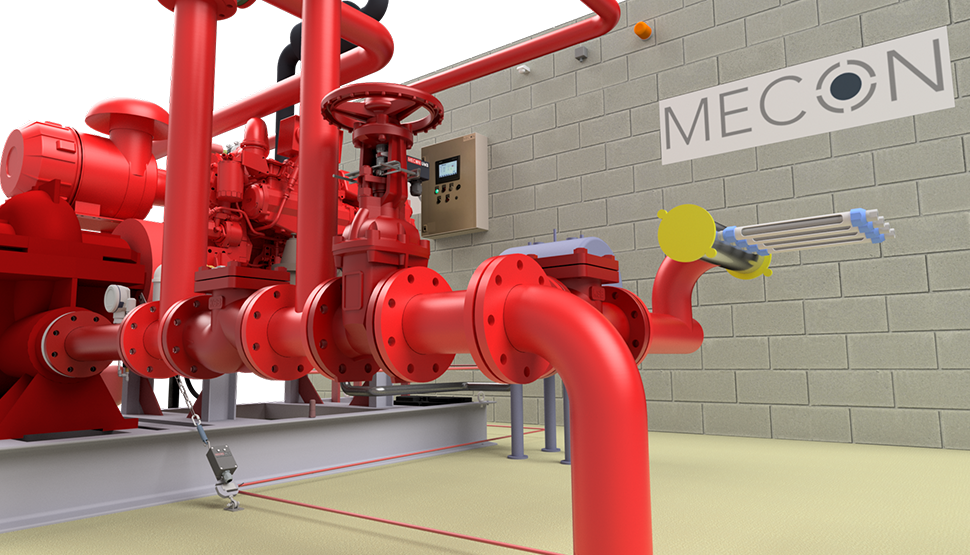

MECON GmbH, located in Kerpen, Germany, has 90 years of experience developing flow measurement and level indication technology. FACTS is an automated fire pump testing system that is used with diesel engine or electric motor driven fire pumps. The automated system fulfills routine fire pump inspection and testing in accordance with applicable jurisdictional requirements and FM Property Loss Prevention Data Sheets.

According to Dr. Joachim Böke, MECON’s Technical Director, “we are excited to have partnered with FM Approvals to complete this certification and confirm that FACTS is another example of the forward-looking solutions we provide customers to give them a significant advantage when overseeing critical elements of fire pump packages in the field.”

In general, fire pump monitoring systems report failures, malfunctions, or negative performance trends. Once one of these items are reported, qualified personnel can investigate and take any necessary actions. These tests have traditionally been conducted by trained personnel at specified frequencies as outlined in FM Property Loss Prevention Data Sheet 2-81, “Fire Protection System Inspection, Testing and Maintenance”. Fire pump monitoring systems eliminate this need. In the event of a problem during the test, it is automatically terminated and the system reports the failure. The automation and technology these systems use allow for significantly improved real-time pump health information, thereby improving reliability. In all cases, these new systems are subordinate to the pump control such that they do not influence the normal starting and operation of the pump in the event of a fire.

The existence of FM 1330, and this unprecedented certification, emphasizes the importance of independent, third-party certification of fire pump monitoring and automated testing.

As an international leader in third-party testing and certification, FM Approvals uses our scientific approach to simulate in real-world circumstances to objectively evaluate product performance. If your organization manufactures or is in search of fire protection or other loss prevention products, access the Approval Guide or contact Witali Engelhardt (Manager, New Business, EMEA) at witali.engelhardt@fmapprovals.com.